Alkaline Zinc Plating provides excellent corrosion resistance and superior adhesion properties for a wide range of metals. This eco-friendly process enhances the durability and appearance of parts, making it ideal for automotive, aerospace, and industrial applications.

Electroless Nickel Plating offers uniform thickness and exceptional wear resistance without the need for an electrical current. This coating delivers superior corrosion protection and enhanced hardness, perfect for complex shapes and critical components in various industries.

Electro Polishing is a precision finishing process that removes surface imperfections and enhances the reflectivity of metal parts. This technique improves cleanliness, corrosion resistance, and overall aesthetic appeal, making it suitable for medical, pharmaceutical, and food processing equipment.

Passivation is a chemical treatment process that removes free iron and other contaminants from stainless steel surfaces. This enhances the material’s corrosion resistance and extends its lifespan, ensuring optimal performance in demanding environments.

Nickel Plating provides a lustrous, corrosion-resistant finish that improves the durability and appearance of metal components. This versatile process is widely used in the automotive, electronics, and consumer goods industries for its excellent wear resistance and aesthetic appeal.

ED Coating, or Electrodeposition Coating, offers uniform coverage and superior corrosion protection for complex shapes and surfaces. This environmentally friendly process is ideal for automotive, industrial, and consumer goods applications, providing a durable and attractive finish.

Chromating is a chemical conversion coating that enhances the corrosion resistance and paint adhesion of aluminum and other metals. This process is essential for aerospace, automotive, and electronic components, ensuring long-lasting protection and performance.

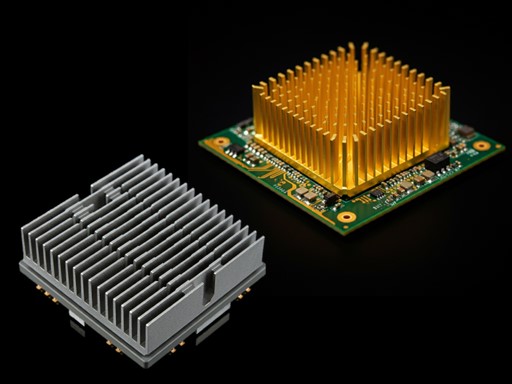

Anodizing is an electrolytic process that creates a durable, corrosion-resistant oxide layer on aluminum surfaces. This finish enhances the material’s aesthetic appeal and provides excellent wear resistance, making it ideal for architectural, automotive, and consumer products.

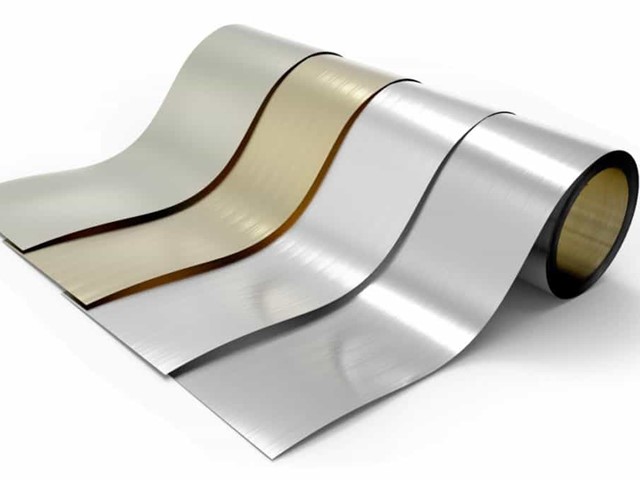

Zinc Nickel Plating offers superior corrosion protection and excellent adhesion properties for a variety of metal substrates. This high-performance coating is widely used in the automotive and aerospace industries for its durability and resistance to harsh environments.

Flash Chrome provides a thin, protective chrome layer that enhances the appearance and corrosion resistance of metal parts. This process is commonly used in automotive, plumbing, and decorative applications for its bright, reflective finish and durability.

Tin Plating offers excellent solderability and corrosion resistance, making it ideal for electronic components and connectors. This process provides a smooth, shiny finish that enhances the performance and longevity of metal parts in various applications.

Hard Chrome Plating delivers a thick, wear-resistant coating that significantly extends the lifespan of metal components. This process provides superior hardness, low friction, and excellent corrosion resistance, making it ideal for industrial machinery, automotive parts, and hydraulic systems.

© 2024 FRONTIER METAL FINISHING SDN BHD. 202101038318 (1438618-V)